Emergency Number

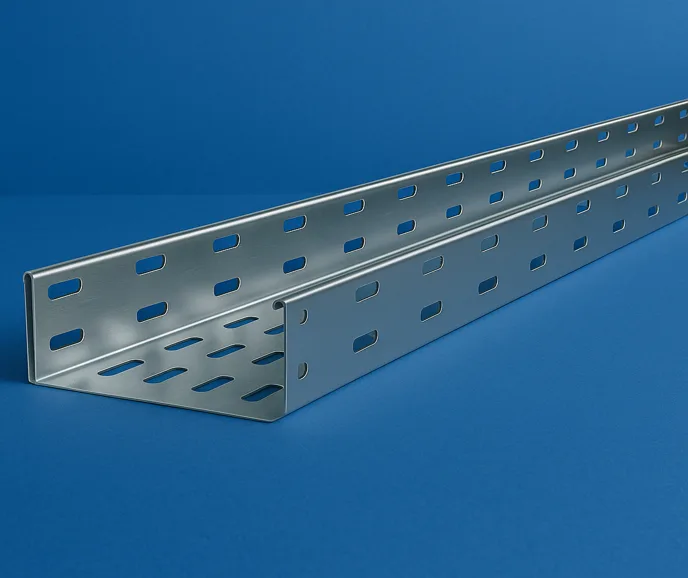

GI Perforated Cable Trays

GI Perforated Cable Trays Manufacturers in Pune

Welcome to Harshdeep Cable Tray, we are leading GI Perforated cable trays,we are aware of the need of efficient cable management,particularly in environments where ventilation and heat dissipation must be maximized. Our GI perforated cable trays are a perfect solution for many uses.

Benefits of GI Perforated Cable Trays

- Improved Ventilation: The increased airflow made possible by our GI perforated cable trays lowers the amount of heat that accumulates around the wires. This is of special importance in environments where heat management is important,such as data centers,power plants, and other locations.

- Reduced Cable Weight: The overall stress on supporting structures decreases when using GI perforated trays as opposed to solid cable trays because of their lower overall weight. This is a highly practical bonus for large-scale projects.

- Simple Cable Visibility: By using our GI Perforated trays you can save time and money by performing maintenance and troubleshooting tasks as effectively and with less effort thanks to the open design.

- Durability and Corrosion Resistance: The protective zinc coating that is provided to the GI material during the hot-dip galvanization process will extend the life of your cable management system.

Why Choose Us For Perforated Cable Trays near Pune?

- Commitment to Quality: We place a high priority on quality in every area of production,make sure that the strength,perforation patterns and corrosion resistance of our GI perforated cable trays meet or surpass industry standards.

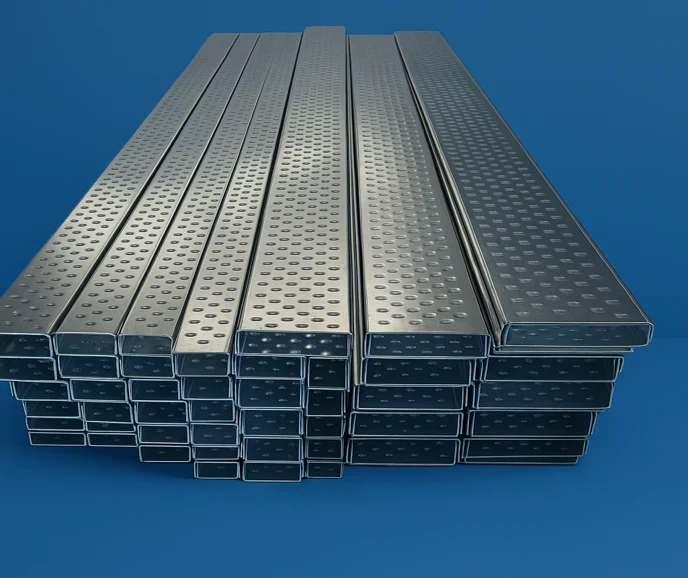

- Product Range: To meet the unique project specifications and airflow requirements,we provide a variety of GI perforated cable trays in different sizes,configurations and perforation patterns.

- Professional Advice: As a leading Perforated Cable Tray manufacturers in Pune,our team of experts is well-versed in the finest methods and uses for cable trays. They will be pleased to help you choose the best GI perforated cable trays to meet the ventilation and cable management needs of your project.

- Local Service Area: As a leading Perforated Cable Trays suppliers in Pune,our company provides quick and effective service across the region. We can also manage projects outside of Pune.

Specifications :

| Width | 50 to 1250 mm |

| Thickness | 10 to 16 SWG H |

| Height | 25 to 150 mm |

| Bend | 10 to 25 mm |

Finishes :

- Hot Dip Galvanised / Epoxy / Powdercoated.

- Epoxy / Powdercoated only.

- Hot Dip Galvanised / Epoxy / Powdercoated.

- Self finish / Epoxy / Powdercoated.

Material of Construction :

- M.S. Hot rolled : IS1079, 1.6mm – 3.0mm

- CRCA Steel : IS513, 1.6mm – 2.0mm

- Pregalvanized M.S. : IS277, 1.6mm – 2.0mm

- Aluminium (Comm.) : 1.6mm – 2.5mm

| Light Duty | Medium Duty | Heavy Duty Flange Type | |

|---|---|---|---|

| Standard Length ‘L’ | 2.5 / 3.0 | 2.5 / 3.0 | 2.5 / 3.0 |

| Slot Dimension | 20 x 10 | 20 x 104 | 20 x 10 |

| Tray Width | 75, 100, 150, 300, 450 & 600 | 75, 100, 150, 300, 450 & 600 | 75, 100, 150, 300, 450 & 600 |

| Tray Thickness | 1.6-2, 0-2, 5-3.0 | 1.6-2, 0-2, 5-3.0 | 1.6-2, 0-2, 5-3.0 |

| Height of Tray | 25/40/50 mm | 50/75 mm | 50/75 mm |

| Flange | – | – | 20 mm |

| Application | Instrumentation | Regular industrial application | Heavy Industrial along with tray covers |

G.I Perforated Cable Trays

G.I Perforated Cable Trays

Contact us today to discuss your GI perforated cable tray requirements and receive a free quote!